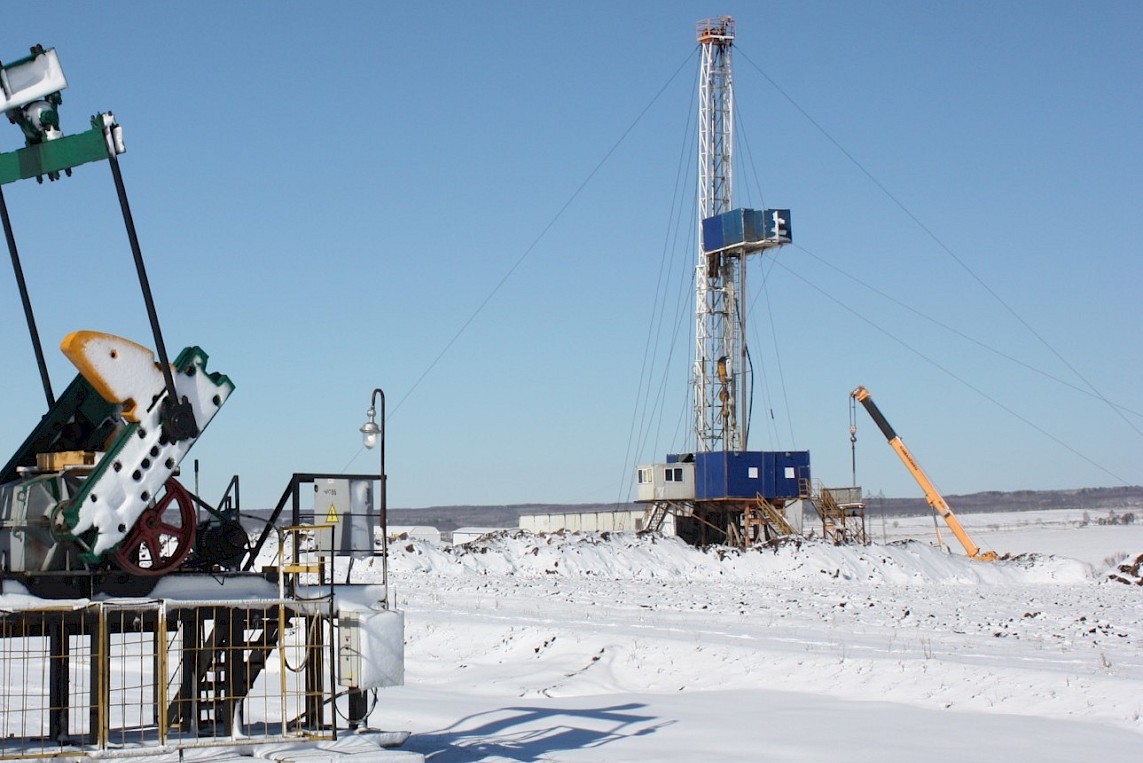

Exploration and production drilling

We take on the function of the General Contractor, becoming the main organizer of the technological process of the construction of the facility, removing this task from the Customer

-

10+ yearsof experience

-

60+completed projects

For more than 10 years we have been working in the field of construction, repair and reconstruction of oil and gas wells, as well as multilateral wells for the extraction of natural resources in the most difficult geological and weather conditions

Технологии

-

Construction of appraisal, exploration and production wells

- construction of appraisal wells to determine oil and gas content;

- construction of exploratory wells to determine the boundaries of the field, calculate reserves and prepare them for development;

- construction of all types of production wells for the development and operation of oil and gas deposits: appraisal, production, injection, observation (control).

-

Construction of multilateral and branched-horizontal wells

The construction of this type of wells provides better field development and an increase in the recovery factor while minimizing the impact on the environment.

We carry out drilling operations with a complex of geophysical surveys in the exploration of deep horizons of the pipe.

-

Construction of directional wells with inclined wellheads in fields of hard-to-recover reserves (HTR)

The extraction of heavy oil and bitumen is complicated by their high viscosity. The method of construction of parallel wells used by our company makes it possible to use them for SAGD technology (from the English. Steam Assisted Gravity Drainage - thermogravitational drainage of the reservoir): it allows you to "warm up" the reservoir and extract the fluid faster and easier. With such an innovative approach, the extraction of HTR is highly profitable.

-

Construction of large diameter wells

The construction of large-diameter wells is in demand by the mining industry for the purpose of degassing and utilizing gases from mines, supplying air to existing mine workings (shafts, adits), as well as for the extraction of minerals that cannot be mined in an open way.

Our company has experience in the construction of these wells in difficult geological conditions, including the use of a unique specialized large-diameter drilling tool.

-

Reconstruction/rehabilitation of wells by sidetracking (ST)

The applied ST technology is an effective method of intensifying the production of all types of deposits, allows you to increase production at mature fields, return idle wells to operation.

-

Сore drilling

We carry out core sampling using core drilling. Core drilling is one of the most effective methods for assessing and determining rock reserves. The method allows to determine the depth of the rock with the highest accuracy. A whole mass of rocks is drilled without disturbing their structure and condition, which makes it possible to conduct a comprehensive analysis of the studied rock.

-

Directional drilling telemetry

- we develop programs for drilling a directional or horizontal well section, including calculation, construction of a design profile, engineering explanations;

- we monitor directional drilling using telemetry systems with a hydraulic or electromagnetic communication channel;

- we analyze the results of drilling operations and prepare recommendations for optimizing the drilling process.

-

Geophysical works and well surveys

- we carry out a complex of field geophysical surveys during well drilling;

- we carry out geophysical surveys on drill pipes and geophysical cable.

-

Cement service

- we prepare and calculate well cementing programs;

- we develop formulations of cement mixtures;

- we cement casing strings of all sizes using standard grouting mixtures, expanding and heat-resistant cement;

- we control the well cementing process.

-

Drilling fluid service

- we provide services for the development of recipes and the selection of the required properties of systems for specific mining and geological conditions and the specifics of drilling in each specific region;

- we provide support for the well construction process.

-

Bit service and bottom hole assembly (BHA)

- we provide services for engineering and technical support and testing of drill bits, aimed at increasing the ROP, as well as improving the quality and wear resistance of the supplied tool;

- we apply an integrated approach to the selection of bits, the design of new modifications of bits for specific geological and technological conditions;

- we constantly analyze the results of the tool development in order to improve the quality of the services provided.

-

Core sampling service

- we extract from the well and perform laboratory studies of rock samples to obtain the data necessary for the construction of geological and geophysical models of the field, assessment of the reservoir properties of the reservoir.